Sabit Montajlı ID Okuyucular

FIX-MOUNTED ID READERS ID-600

FOR ADVANCED CODE-READING TASKS IN SMART PRODUCTION

Our ID-600 offers outstanding versatility for the highest degree of productivity in versatile production systems.

he compact, versatile ID readers of the ID-600 series convince with an upgradeable software scope, a clever and robust illumination concept, M12 interchangeable optics as well as extensive optics accessories.

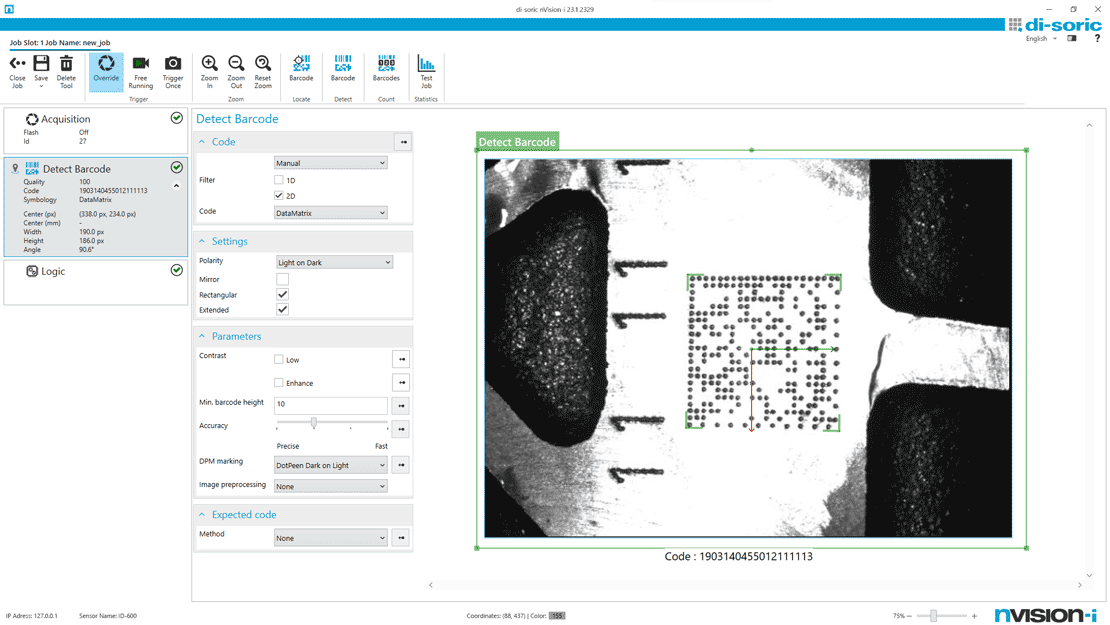

Industry-leading algorithms for high read rates

The ID-600's software-integrated image correction and calibration to optimize image quality guarantees excellent images in terms of distance, field of view and resolution.

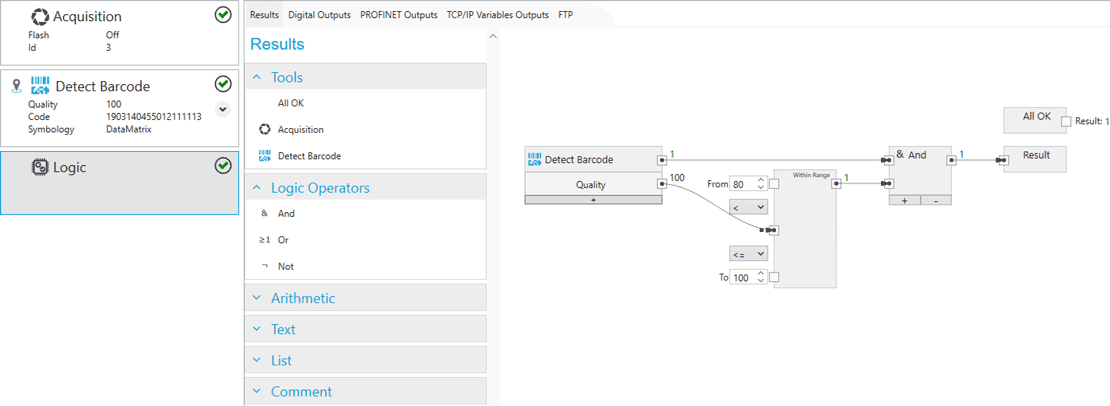

With the quickly configurable nVision-i software and the comprehensive code reading tools, optimum performance is achieved with smooth startup and changing requirements. If required, the tools can be extended by a software upgrade or individually optimized by customizing.

The versatile Profinet connection to the existing PLC module and image transfer via FTP/SFTP round off its flexibility

Integrated high power LED illumination

in red and white, switchable via software

for optimal startup at a high speed and at a large working distance.